Smart materials are those whose properties change significantly in response to environmental change. Thus, controlled environmental change (i.e. temperature, pressure, etc.) can be used to drive material property changes that enable actions without moving parts. The fundamental research and the systems being developed to incorporate these new materials and technologies are highlighted by the ASME (American Society of Mechanical Engineers) in their annual SMASIS (Smart Materials, Adaptive Structures, and Intelligent Systems) conferences.

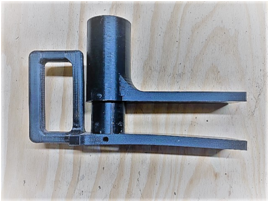

Actuators are among the more common uses for smart materials in this phase of their evolution, and linear actuators the most readily available. Actuators are devices that move due to some stimulus provided by the user. A linear actuator moves back and forth. The motion might be driven manually, as in a light switch, or by some electro-mechanical process. For Shape Memory Alloy (SMA) actuators, the driving force is a change in the material properties of the SMA element. These property changes, such as shape or length, can be used to produce work.

Type, form, composition, and training are essential elements of smart material creation and use. Knowledge of these for specific smart materials is key to the successful implementation of new product designs. A commercially available form of trained SMA is a 50-50 mix of nickel and titanium (NiTi, nitinol) wire.

Several universities have created special departments to focus on this technology, such as the University of Alberta who has good definitions and some great images. A consortium of industry, academic, and government organizations, www.casmart.org, is focused on shape memory alloys, and those conducting research in this field present at the ASME annual SMASIS conference.

The State of the Art

A consortium of, government, academic and industry partners dedicated to identifying manufacturing standards and technology methods to support the emerging Smart Materials industry.